Quality controlling, process controlling

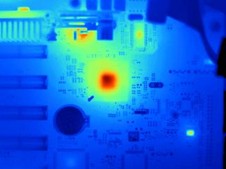

With the ability in viewing small, irregular shaped objects and remotely determining the small characteristics and temperatures, infrared cameras have been valuable assets to both production and diagnostic areas in the electronics industry. They enable electronics companies to quickly identify electrical problems in their products before having to encounter more severe problems down the road.

With the ability in viewing small, irregular shaped objects and remotely determining the small characteristics and temperatures, infrared cameras have been valuable assets to both production and diagnostic areas in the electronics industry. They enable electronics companies to quickly identify electrical problems in their products before having to encounter more severe problems down the road.

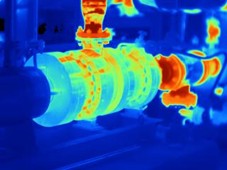

As it is extremely energy intensive, the process of petrochemical manufacturing requires careful thermal monitoring to ascertain safety and thermal efficiencies of each process. Examining such thermal processes with high temp- measuring infrared thermal camera can provide a quick and accurate diagnosis of problems and save refineries high damage-related costs.

As it is extremely energy intensive, the process of petrochemical manufacturing requires careful thermal monitoring to ascertain safety and thermal efficiencies of each process. Examining such thermal processes with high temp- measuring infrared thermal camera can provide a quick and accurate diagnosis of problems and save refineries high damage-related costs.

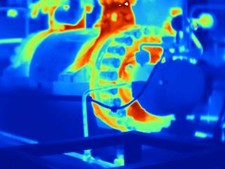

Food processing companies are constantly stumbled by boundaries of safety, product quality and economy. IR thermal imaging makes it easy to get out. IR thermal imaging provides the measurement capability to safely and economically achieve a high quality and thus accomplishment of a company in the increasing vehement competition for market share.

Food processing companies are constantly stumbled by boundaries of safety, product quality and economy. IR thermal imaging makes it easy to get out. IR thermal imaging provides the measurement capability to safely and economically achieve a high quality and thus accomplishment of a company in the increasing vehement competition for market share.

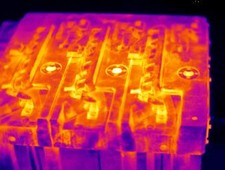

The temperature watching process is inescapable for glass industry and china industry. Since the nature of the process is thermal the quality of the wrought glass depend on the devices, moulding, conveyor belt, boiler adjustments. The thermocameras is easy-to-use for temperature monitoring, and onto antecedent maintenance of electronic and mechanical problems.

The temperature watching process is inescapable for glass industry and china industry. Since the nature of the process is thermal the quality of the wrought glass depend on the devices, moulding, conveyor belt, boiler adjustments. The thermocameras is easy-to-use for temperature monitoring, and onto antecedent maintenance of electronic and mechanical problems.

Advised products: